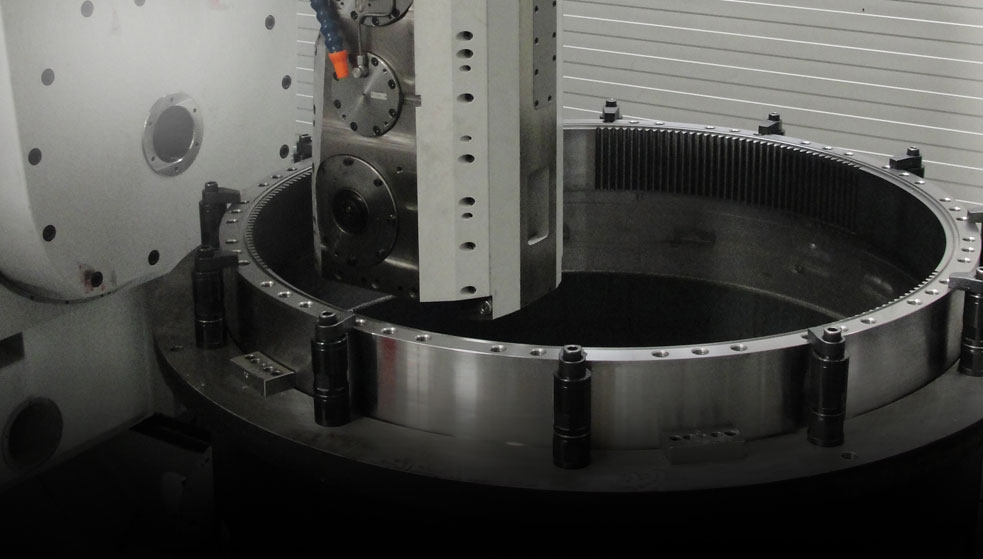

CNC Machining of a Steel Ring Gear for the Large Mining Equipment Industry

| Product Description | Clutch Plate Housing |

|

Capabilities Applied/Processes |

Primary:

Secondary:

|

|

Equipment Used to Manufacture Part |

1 Meter Vertical Turning Center 2.4 Meter Gear Gasher |

|

Overall Part Dimensions |

1285mm (50.6 in) Outside Diameter |

|

Tightest Tolerances |

+/-.05mm (.002 inch) Diameter |

| Material Used |

4140 Steel Forging |

| Material Finish |

Surface finish on gear tooth .015(μin.) |

|

In process testing/inspection performed |

On-machine inspection with gages or Faro Arm. |

| Industry for Use |

Large mining equipment |

| Volume |

140+ Pieces per Month in Production |

| Standards Met |

Customer Specifications |

|

Project Highlight |

This ring gear demonstrates our precision gear gashing capability. Quality achieved includes the following; profile class 13, lead class 12, and index class 11. |

© 2014 Richardson Manufacturing Co. All rights reserved. Privacy Policy | Sitemap | Careers Site created by Resolute Design