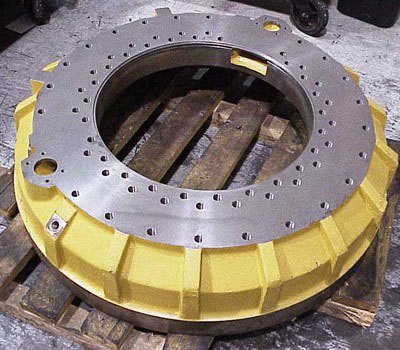

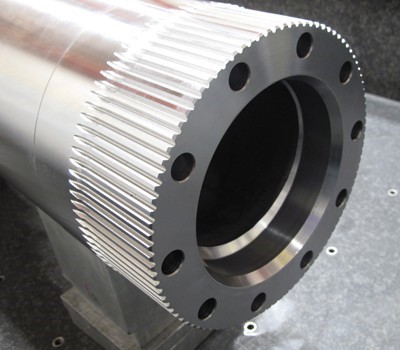

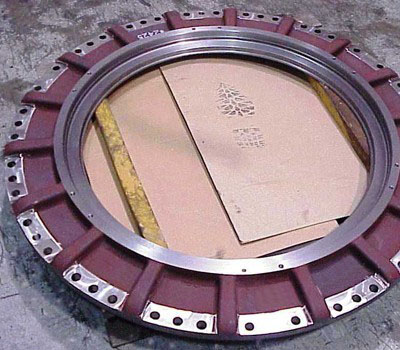

Richardson Manufacturing Company specializes in high-precision horizontal and vertical milling and

boring operations. We routinely hold tolerances of +/- .0005” in addition to rough machining at high

metal removal rates. Richardson Manufacturing utilizes milling centers with up to 4000mm of X-Axis

travel and 3000mm of Y-Axis travel. These machines are equipped with pallet changers that allow

us to maximize productivity and reduce downtime for setup. Touch probe technology is utilized on

the machines to align workpieces as well as for on-machine inspection. 5-axis mill-turn and 5-axis

machining centers allow us to complete parts in one operation that might normally require two or

three.

We also have the capability of contour boring of profiles and tapers. We pride ourselves on our creativity in workholding, cutting tool application, and process development. We work diligently with our customers to meet cost, quality, and delivery requirements. Common applications include machining of ductile iron castings and steel forgings and castings.

| CNC Horizontal Milling Capacity | CNC Vertical Milling Capacity | |

| Tolerances | ±.0005” / ± 0.0127 mm | ±.0005” / ± 0.0127 mm |

| Workholding | Custom fixtures and chucks designed and built in house as needed. | Custom fixtures and chucks designed and built in house as needed. |

| Max. Part Weight | 44,000 lbs (20,000 kg) | 8,800 lbs (4000 kg) |

| X Axis Travel | 160 in / 4,064 mm | 78.74 in / 2,000 mm |

| Y Axis Travel | 120 in / 3,048 mm | 55.12 in / 1,400 mm |

| Z Axis Travel | 60 in / 1254 mm | 29.53 in / 750 mm |

| Axes | X, Y, Z, W, and contouring B axis | 5 axis Mill turn |

| Pallet Range | 600 mm x 600 mm to 1,800 mm x 2,500 mm |

1,000 mm x 1,000 mm to 1,250 mm x 2,240 mm |

© 2014 Richardson Manufacturing Co. All rights reserved. Privacy Policy | Sitemap | Careers Site created by Resolute Design