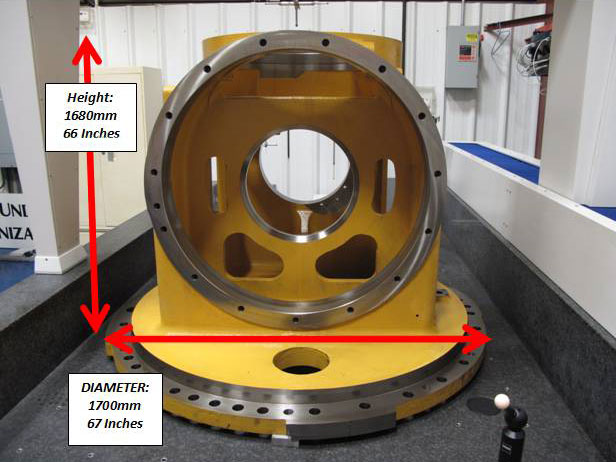

CNC Machining of a Ductile Iron Differential Housing for the Large Mining Vehicle Industry

|

Capabilities Applied/Processes |

Primary: Secondary: |

|

Equipment Used to Manufacture Part |

130 Horizontal Boring Mill |

|

Overall Part Dimensions |

Base Diameter: Ø 67” |

|

Tightest Tolerances |

± 0.05mm (0.002 inch) Diameter |

| Material Used |

Ductile Iron |

| Material Finish |

RA 63 |

|

In process testing/inspection performed |

On-machine inspection with gages and Faro Arm |

| Industry for Use |

Large Mining Vehicles |

| Volume |

3 – 20 Piece Batches |

|

Delivery/Turnaround Time |

20 Day Lead Time |

| Standards Met |

Customer Specifications |

|

Project Challenges |

This component requires large boring applications as well as the ability to maintain tight true position of these bores to each other. |

© 2014 Richardson Manufacturing Co. All rights reserved. Privacy Policy | Sitemap | Careers Site created by Resolute Design